Arsenic removal - Case Study

Initial situation:

The brewery of this case study secures its water su pply from its own wells. However, the well water is contaminated with arsenic. The alternative supply from the municipality would cause substantial additional costs and limit the independence of the brewery with resp ect to its water supply. Therefore the well water had t o be significantly reduced in its arsenic content - in a ddition to other treatment steps. In this particular case the target was set at 5 ppb , well below the drinking water limit of 10 ppb in order to balance the inevitable entry of arsenic into the beer through other raw materials and process aids.

Initially, the brewery filtered its well water over granulated iron hydroxide (GEH), whereby the desired arsenic reduction was achieved. However, the operating costs went completely out of control as the GEH filter material needed to be changed frequently as GEH not only removes arsenic from the water, but loses some of its capacity through its affinity towards other water constituents such as silica. Regeneration of the GEH material within the filtration system was not economically feasible, a complicated and expensive filling replacement was the only choice open to the brewery. For that reason the brewery asked EUWA for an alternative treatment proposal.

The EUWA solution

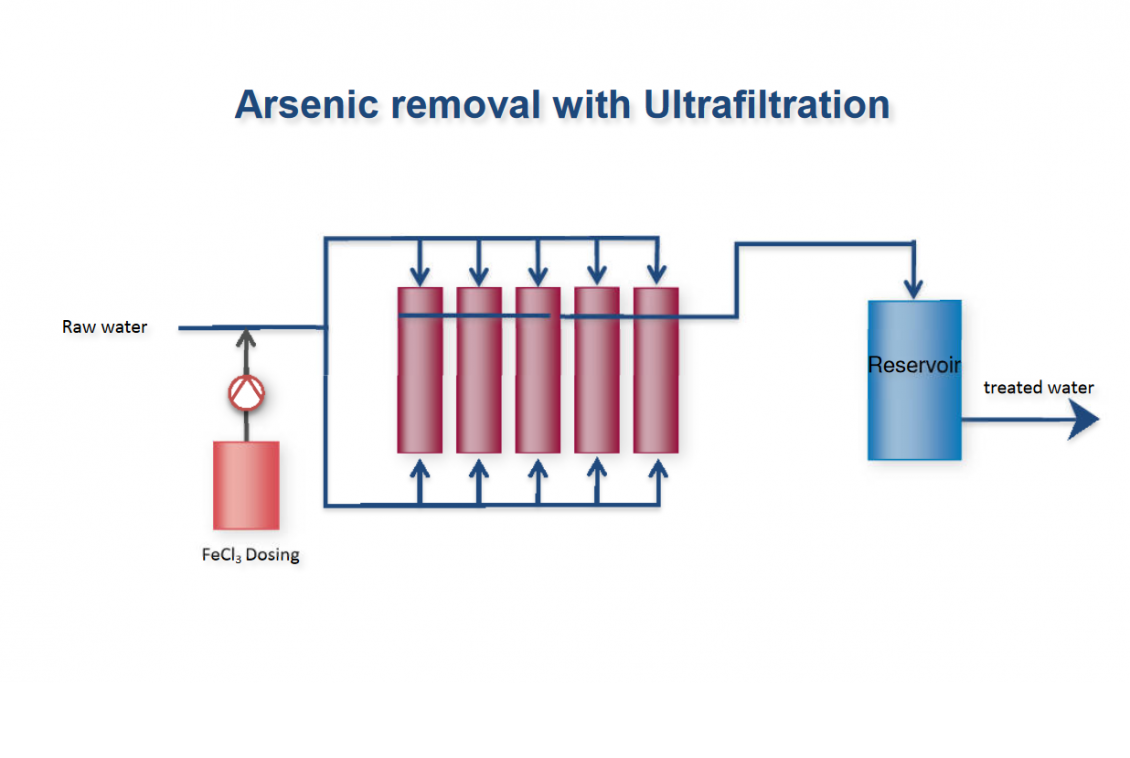

The realised EUWA concept consists of an ultrafiltr ation unit with an upstream FeCl3 dosage. In a first step arsenic contained in the well water is flocculated with ferric hydroxide, and then removed from the water through the subsequent ultrafiltration. Practical experience Since the commissioning of the EUWA process, the brewery reduced the arsenic content of its well water safely to the desired value. At the same time, ultrafiltration removes turbidity and also acts as a microbiological barrier.

In contrast to the previous solution no expensive and complex replacement of filter material is necessary, the ultrafiltration can be cleaned periodically by flushing with water or chemically enhanced flushing. The operating costs are significantly lower compared to filtration with GEH. Therefore, the investment in the new EUWA plant has paid off in less than two years.

- Performance: 40 m³/h

- As content in the feed: ca. 20 μg/l

- As content in the expiration: < 5 μg/l

- no GEH necessary

Interested?

At EUWA, good service is of high priority.

That's why we would like to advise you personally and competently. Make your request here and we will get back to you as soon as possible.

Representation of arsenic removal in this case study

Downloads

Here you will find current downloads with further information.