Ultrafiltration

Ultrafiltration is a modern alternative to the clas sical sand and multimedia filters like the reverse osmosis a pressure-driven membrane process. It removes any ki nd of particles from the water. Compared to microfiltr ation it has a smaller pore size and thus holds back bact eria and viruses to > 99.999%. Thus, the ultrafiltration is an effective microbiological barrier.

The filtrate is independent from raw water quality fluctuations reliable free from particle and turbid ity. As pre-treatment of a reverse osmosis, it also reduces the fouling potential of the raw water significantly. Due to its sterilizing effect ultrafiltration plays an increas ingly important role in the field of water recycling.

The ultrafiltration provides a constant good and compared to classical sand and multimedia filter significantly better filtrate quality even with flu ctuating raw water qualities.

With sand and multimedia filte r a Ultrafiltration retention of approx. 10 μm is achieved while ultra- filtration provides an absolute barrier with its po re size of approx. 0.02 μm. If a flocculant is used to reduce the organic load of the water, with an ultrafiltration, in contrast to conv entional flocculation, the formation of small flocs is suffi cient to remove them from water, which enables a more stable process. At higher turbidity values the UF can be combined with a lamella settler upstream. Further f ields of application are the removal of iron, manganese, arsenic or as filtration stage after a lime precipi tation reactor.

Pressure <1 bar, yield> 98%

Due to their high stability hollow fiber membranes have prevailed in ultrafiltration. They can be backwashe d, which significantly enhances the possibilities of removing deposits. The membranes used in ultrafiltration are made of polyethersulfone and thus chemically very stable , so that they can be regularly rinsed with acid and cau stic and disinfected with oxidizing agents such as chlor ine. The usual pressure range is <1 bar, which makes ultrafiltration also from an energetic point of vie w an interesting process. The filtration in dead-end mode is preferred becaus e of its low energy consumption. In this case the yield is determined by the duration and the frequency of the backwash.

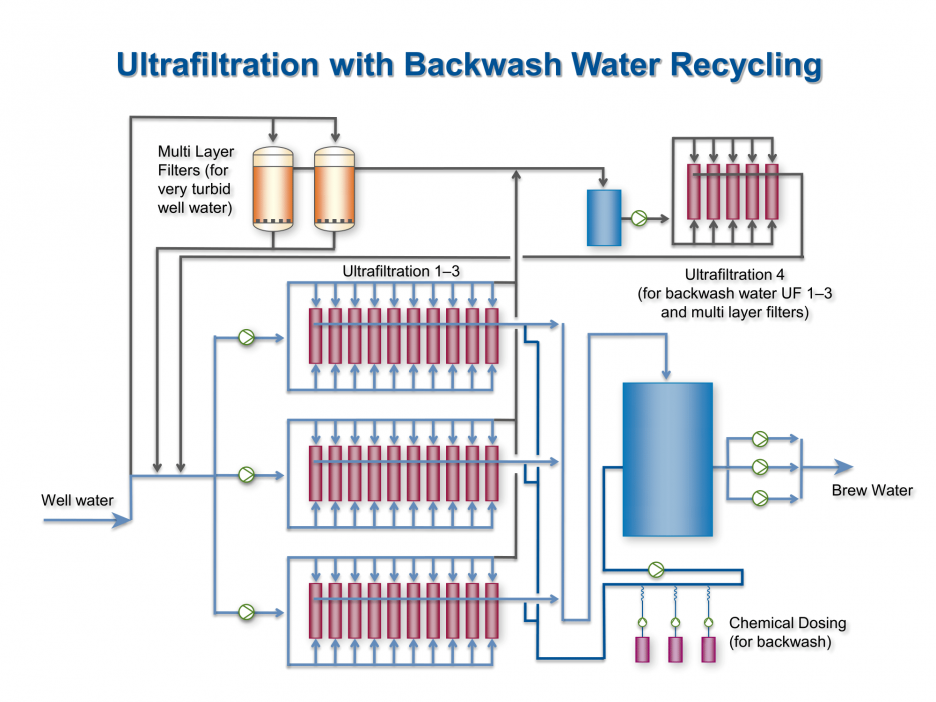

Chemical cleaning or backwash are trigger ed on demand based on the differential pressure build- up across the membrane caused by the particles removed from water. Depending of the raw water quality yields of > 98% can be achieved and may even be increased to 99% in combination with rinse water recycling. Only for wa ters with high particle load the ultrafiltration membran e is operated in cross-flow mode with a permanent partic le discharge.

Interested?

At EUWA, good service is of high priority.

That's why we would like to advise you personally and competently. Make your request here and we will get back to you as soon as possible.

Ultrafiltration with backwash water recycling

Downloads

Here you will find current downloads with further information.